Welder’s Performance Testing – Navy COOL

$ 250.00

Thru the Navy COOL program, navy personnel are completing welder's performance testing at Integrity Welding, LLC. When successful, these sailors are able to use the performance test results to apply for American Welding Society welder's certification.

- Code: AWS D1.1 (Structural Welding Code – Steel)

- Process: SMAW (Shielded Metal Arc Welding)

- Welding Procedure: SMAW-U-WPS

- Electrode: E7018, 1/8″ diameter

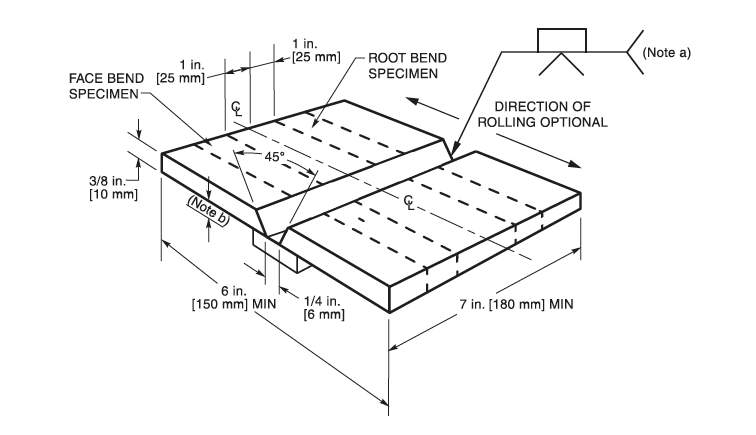

- Material: 3/8″ thick ASTM A36 Steel Plate

- Dimensions: 3” x 6” with 22.5° bevel

- Position(s): 3G (Vertical) or 4G (Overhead)

Acceptance Criteria (Visual Examination)

Each test plate must meet the requirements specified in AWS D1.1 Section 4.22.1:

- The weld shall be free of cracks

- All craters shall be filled to the full cross section of the weld

- The face of the weld shall be flush with the surface of the base metal (undercut shall not exceed 1/32” and weld reinforcement shall not exceed 1/8”)

- Test plates shall be free from arc strikes

Acceptance Criteria (Mechanical Testing)

Two test specimens will be cut from each test plate. All specimens will then be bent in a bend jig.

For acceptance, the convex surface of the resulting U-shape must not contain any defects exceeding the dimensions specified in AWS D1.1 Section 4.22.5:

- 1/8” maximum dimension for a single discontinuity

- The maximum sum for all discontinuities shall be equal to or less than 3/8”